|

|

|

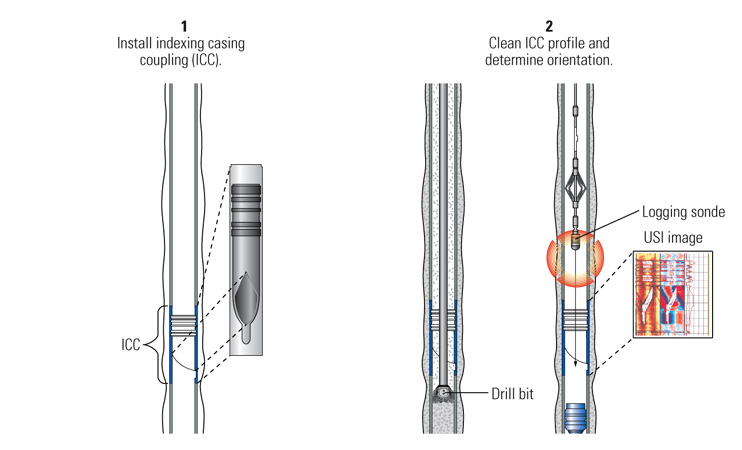

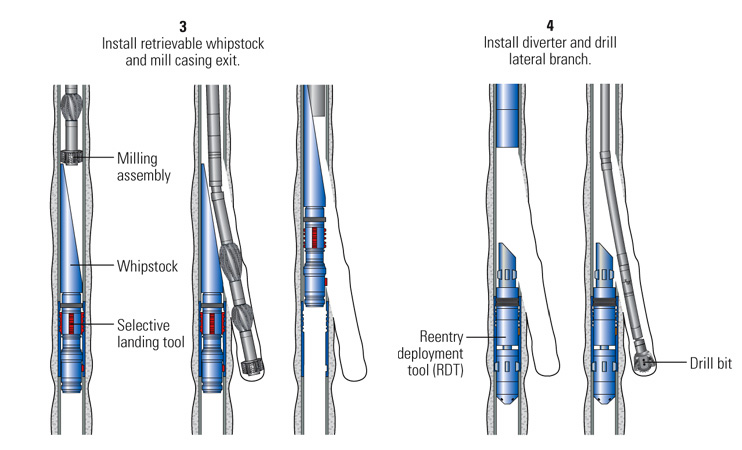

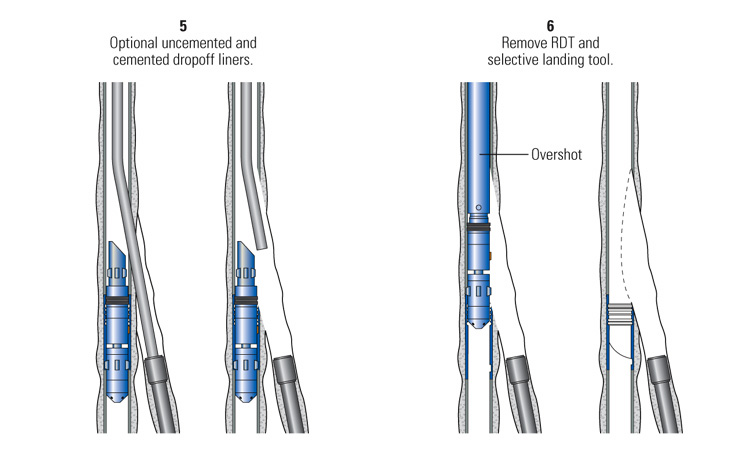

Milling Casing Windows

The RapidAccess system uses an indexing casing coupling (ICC) installed

in the primary casing to mill exit windows for openhole laterals.

The fullbore ICC serves as a permanent depth and directional orientation

reference for drilling or reentry operations, allows conventional

cementing operations and provides a platform for constructing RapidConnect

and RapidExclude junctions.

A two-stage process using a whipstock followed by a special reentry

deployment tool (RDT) improves window milling and junction construction

compared with systems that just use a whipstock. The RDT outside diameter

is smaller and easier to retrieve than standard equipment, which minimizes

debris and tool-retrieval problems after drilling. Redundant tool-retrieval

features further ensure access to lower laterals.

Wireline or measurements-while-drilling (MWD) tools determine ICC depth

and directional orientation so a selective landing tool can orient

the whipstock and milling assembly in a specific direction. The ICC

position also can be determined from USI UltraSonic Imager log data

acquired during CBT Cement Bond Tool evaluations, eliminating one logging

run.

| |