|

|

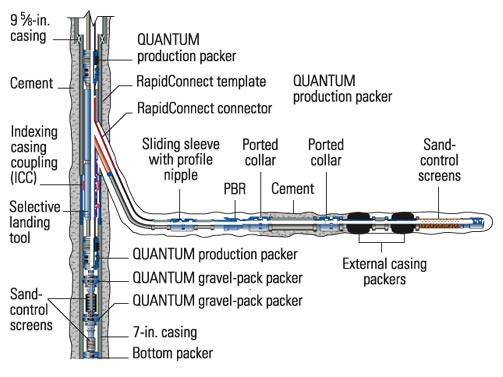

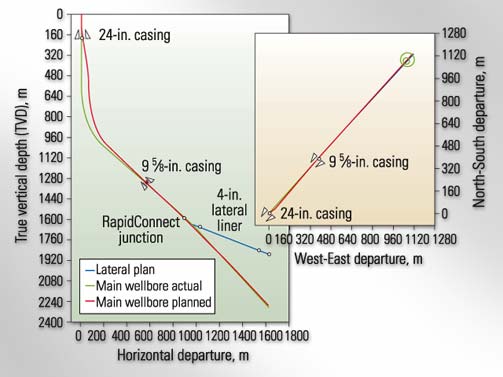

RapidConnect Junction, Nigeria In March 2000, Total installed the first 7-in. RapidConnect junction system in Ofon 26, a new well located offshore Nigeria, West Africa. The design called for a cased and cemented main wellbore with a cased and cemented lateral liner connected to the primary casing, but not cemented at the junction.[note 2] The main wellbore targeted two productive zones; a single lateral tapped a fault-isolated section of the upper zone. Total individually gravel packed the two producing zones in the main wellbore, oriented a whipstock using an ICC in the 7-in. primary casing and then milled an exit window to drill a 6-in. lateral. |

After cementing the 4-in. dropoff liner and cleaning out excess cement, the operator retrieved the upper 4 1/2-in. liner assembly.

Production tubing and completion equipment were connected to the RapidConnect template; a sliding sleeve adjacent to the junction isolated and selectively controlled lateral flow. An isolation packer between the lower screen assemblies in the main wellbore allowed selective production from either interval.

| 2. Ohmer H, Brockman M, Gotlib M and Varathajan P: “Multilateral Junction Connectivity Discussion and Analysis,” paper SPE 71667, presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, September 30–October 3, 2001. |

| |