|

|

RapidExclude Junction, Venezuela

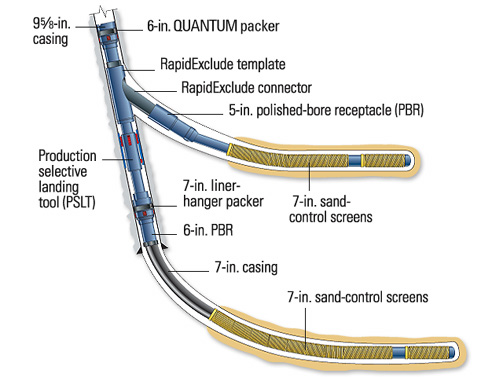

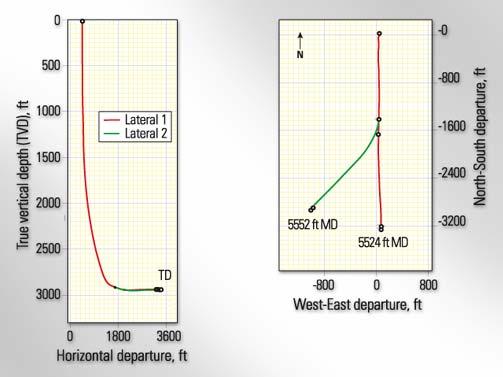

Petróleos de Venezuela S.A. (PDVSA) installed the first Level 3 RapidExclude system in Bare field near Maturin, Venezuela. PDVSA designed the dual-lateral MFB-642 well to accelerate hydrocarbon production. The first lateral was drilled to a length of 1600 ft [488 m] and completed with 7-in. stand-alone screens below a 6-in. polished-bore receptacle (PBR) and liner-hanger packer. A temporary bridge plug isolated this lower lateral. A primary and backup indexing casing coupling (ICC) each with a unique profile installed in the 9 5/8-in. main casing supported milling, drilling and junction construction. Measurements-while-drilling (MWD) tools oriented a retrievable whipstock in the primary ICC. |

A RapidExclude template above a production selective landing tool (PSLT) with tailpipe and a seal assembly was stabbed into the PBR of the lower liner. Then a RapidExclude connector was engaged in the template and tied into the upper liner PBR.

A deflector assembly, or selective through-tubing access (STTA) tool, was run to facilitate coiled-tubing operations in the upper lateral. The STTA was removed to produce from both laterals.

| |